LSR Liquid Silicone Injection Molding Process for Medical Resuscitator Valve

LSR Liquid Silicone Injection Molding Liquid Silicone Injection Molding, also known as LSR Molding, Liquid Silicon Rubbe

Description

Basic Info.

| Runner | Cold Runner |

| Design Software | Pro-E |

| Installation | Semi Fixed |

| Certification | CE, ISO, FDA |

| Standard | FDA, RoHS, SGS, Igs |

| Customized | Customized |

| Applications | Infants Products, Medical Devices, Electronic, etc |

| Sample Time | 12-15 Days |

| Mold Steel | S136 Heat Treatment, Lkm, 718h |

| Properties | Biocompatibility, Low Compression Set, FDA Grade |

| Tolerance | -/+0.01mm |

| Moulding Life | 1000000 Times |

| Color | High Transparent |

| Transport Package | Poly Bags, Carton Boxes |

| Specification | Customized |

| Trademark | Better |

| Origin | Xiamen, China |

| HS Code | 847740900 |

| Production Capacity | 50sets/Month |

Product Description

LSR Liquid Silicone Injection Molding

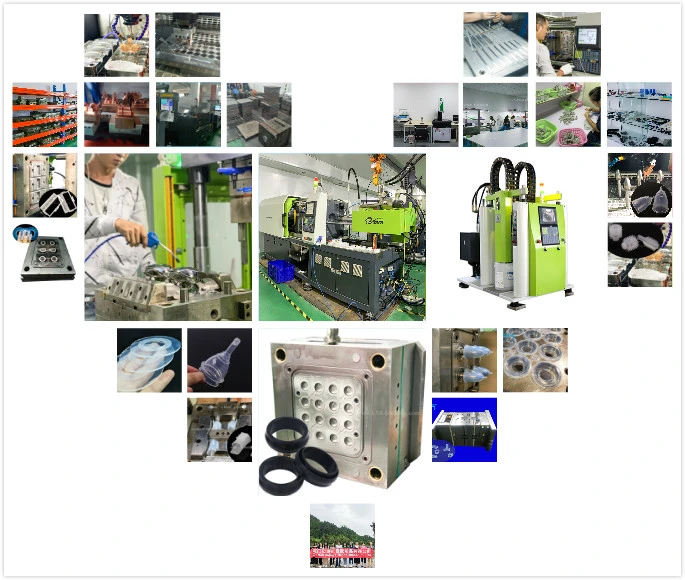

Liquid Silicone Injection Molding, also known as LSR Molding, Liquid Silicon Rubber Molding and silicon injection molding, which is an injection machine to produce pliable, durable and high precision LSR medical accessories, food grade Liquid silicone products electronic parts and automobile parts.

Better Silicone is a professional liquid silicone rubber(LSR) injection molding manufacturer & Liquid injection molded factory, which not only make LSR mold-making and Silicone injection molded prodction, but also offer LSR molded products modability& manufacturability analysis, cold runner systems(Shut off valve) liquid injection mold design service etc.

=

Liquid Injection Molding Main Parts:LSR dosage system, which includes two raw material tubesControl system(Static Mixer) Heating Channel and Cooling ChannelLSR Injection Molding: Vertical and Horizontal.Horizontal moulding machine: with horizontal code mold, easy to achieve automatic production.Horizontal direct pressure clamping ensures the clamping force be steady and equally distribution.Vertical silicon injection molding machine: with vertical mold, standing frame mold, requires manual pick and place products, such as Insert molding. Vertical clamping, vertical injection. Space-saving compact design makes the product take-out more convenient.Liquid Injection Molding advantages:

| Small Parting Line | No & Less silicone flashing, even 2-shots & overmolded with plastic or metal etc. |

| Safer | Platinum Cured, more safe FDA silicone. |

| High Efficiency | Short Cycles, espcially, for mass manufacture. |

| Other advantages | like high purity, more transparency, highly tensile strength, highly tear resistance etc. |

Compression silicon rubber molded parts tolerance, can be +/- 0.02mm, like for medical device, smart cell phone, electronic and so on.Our company not only can produce normal precision liquid silicone rubber products, but also can make metal + liquid silicone & plastic + liquid silicone rubber over-molding products.

Liquid Injection Molding flow/sulfur analysis:1) The vulcanization chemistry of liquid silicone rubber requires a certain reaction time.2) Ideal flow, within diameter 2mm, 170cm, and flow distance is more than 100cm.3) Small thickness 1/1000mm4) Excessive mold temperatures will cause vulcanization, which cause the flow to be blocked.5) Laminar flow can avoid bubbles6) High-speed injection will cause turbulence7) The viscosity of the material will change the flow pattern8) Turbulence leads to white spots.So,in the process of molding making, we need to pay attention to the following aspects:

- using a small plastic injection port to avoid turbulence and spray.

- Use needle or wing rubber injection

- Use a T-shape guide bolt rather than a cylindrical guide bolt

- use an air gun to remove products from the mold

- Add an insulation/board.

- Use toluene and xylene instead of rust inhibitor/oils which contains inhibitors.

Xiamen Better Silicone Import and Export Co., Ltd, not only can make rubber compression tooling & plastic injection molding, produce silicone rubber compression parts & products, but also can make liquid silicone rubber injection mold and produce liquid silicone products.Four production plants:Mold-Making PlantsSilicone Rubber Compression PlantPlastic Injection PlantLiquid Silicone Rubber Injection Plant

OEM/ODM Service:Quickly Quotation Demands:1. 2D/3D designs Drawings, Samples, or other basic information2. Materials Demands: LSR(Liquid Silicone Rubber); Silicone Rubber: NBR, SBR, EPDM, HNBR, TPU, PTV, NR, CR, Silicone etc.3. Materials Hardness: 10 Shore A - 90 Shore4. Sizes Tolerance: +/-0.005mm - +/-0.3mmSpercial demands: like Surface, Color, Anti-Fire/Dust/Water, Working Temperature, Sign NDA etc, please feel free to communicate

Our Contact

Send now