High

Description

Basic Info.

| Model NO. | SMT |

| Customized | Customized |

| After-sales Service | Online Support, Spare Part Video Technical Support |

| Mould Life | 3.5 Million Shots |

| OEM/ODM | Available |

| Mould Material | P20, S50c, 4Cr13, S136, etc. |

| Transport Package | Wooden Case |

| Specification | 0.5ml-60ml Syringe |

| Trademark | SMARTELL |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 30sets/Month |

Product Description

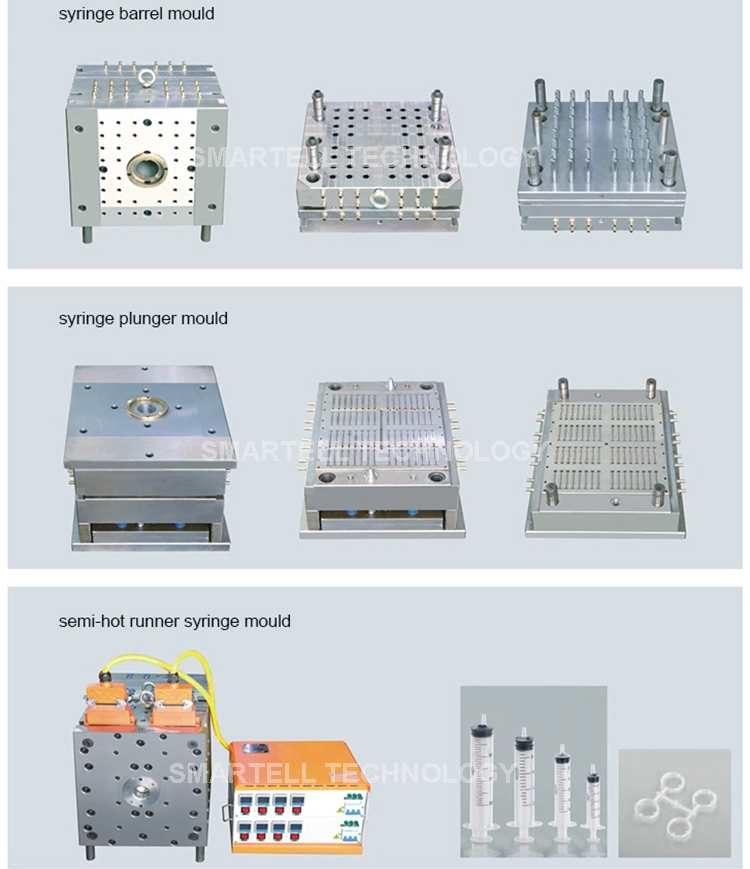

Plastic Syringe/Needle/Gasket/IV Set Injection Mould/Mold

The price of mould always is a topic that people concerned .Actually the quality of mould should be thought first before the price for it's the basic condition of products. It's worthwhile for having a relatively high price mould but can provide you the best quality products with long service time. That's what I say the best mould .

The quality : Mould's quality is up to the level of product knowledge. Using the right mould materials, right processing technology and the right mold structure can make the best mold. Only professional medical consumables mold manufacturers an do this for you .We can say that in the same period, the same price, our quality is best.

After Sale: One year free repair, life-long maintenance. Mould from our company, free maintenance would

always be provided to the customer to remove the trouble back at home.

Mold service life: There have soft mold, hard mold and super hard mold in injection mold industry. In theory, soft mold life is expected to be five hundred thousand times, hard mold for one million times, super hard mold for more than one million times. But it turns out to be the theoretical value for the mold maintenance by user make a great difference of mold life. But we can ensure you in the terms of mould material, processing technology and mold hardness processing , to make the mold most times use in normal use.

Business Flow Chat1.Enquiry | Our customers send drawing or 3D with detail information to us. |

↓ | |

2. Quote | According to the details,we make an offer. |

↓ | |

3. Negotiation | The material,delivery time,payment ,price and ect. |

↓ | |

4.Place an order | Contract Examing&Commenting. Customers do the first payment. |

↓ | |

5.Mould Design | Mould Structure Drawing and Auditing. |

↓ | |

6.Mould Make | Before making,we send design to customer to approve. |

↓ | |

7.Test Sample | We send the test sample to customer until meet customers'requests. |

↓ | |

8.Delivery | Delivery by sea or according to customer's requirment |

Our Contact